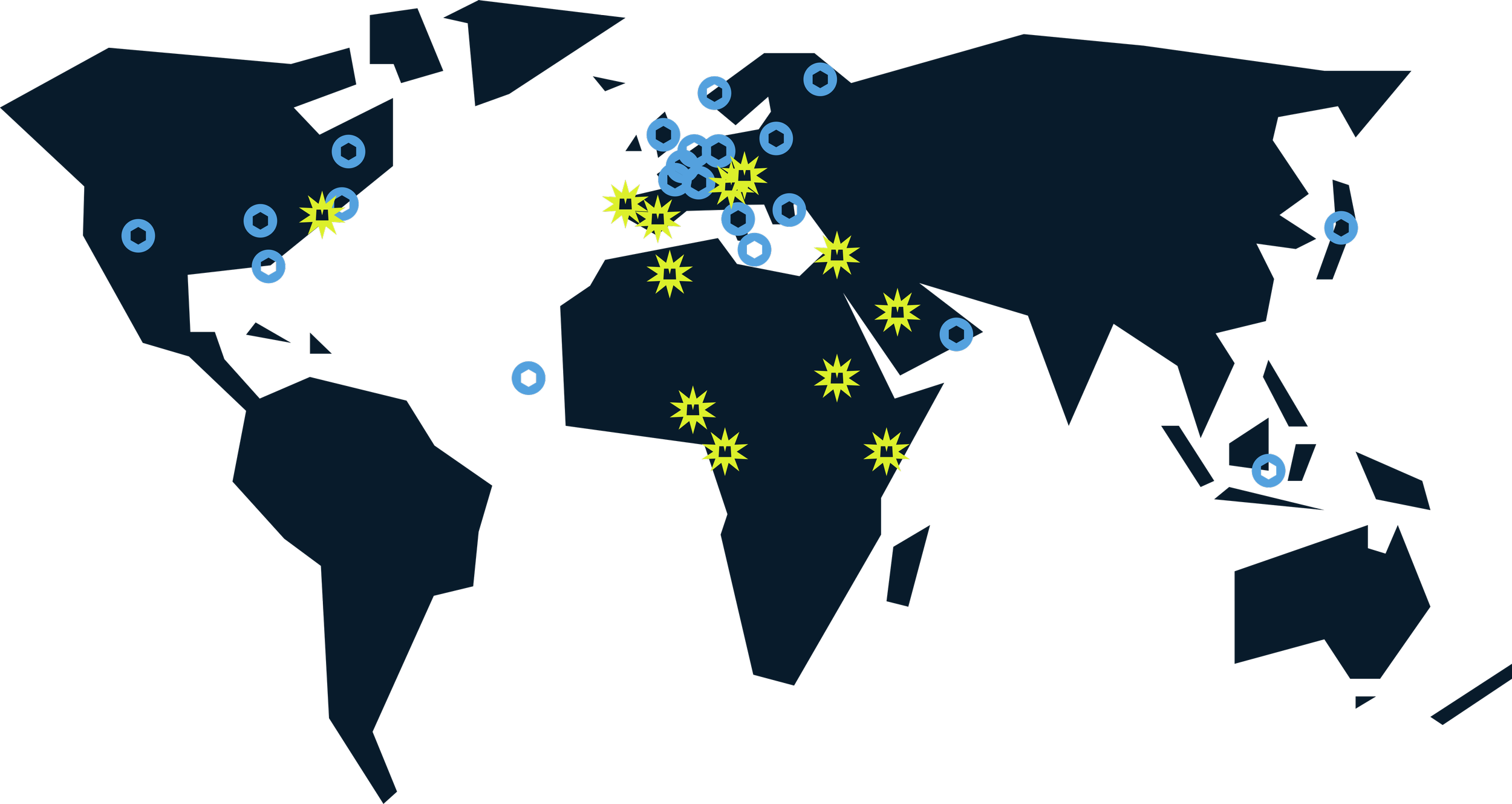

Where are we active?

Places where we’ve done a project and sold machines

Places where we’ve sold machines

SOME OF OUR FAVORITE STORIES

Small scale recycling workshop inside an aluminium and PET recycling facility in Port-gentil, Gabon.

GABOn

2023 / 2024

-

The factory was receiving large amounts of plastic waste that they couldn’t process. With no solution available, most of it ended up being burned.

-

The facility was already recycling cans and PET bottles. PET bottles were baled and exported to China, but the bottle caps, which were a great plastic source for our machines, had no use and were being discarded.

This meant a valuable and clean plastic stream was being wasted. Additionally, as a waste facility, they were receiving many other types of plastics they couldn’t recycle, which also ended up being burned. During our visit, we identified these waste streams and showed how they could be repurposed through our recycling machines.

-

We began with on-the-ground market research in 2023, visiting different cities to identify the best location for the first pilot project in Gabon. We met with local NGOs and initiatives working on plastic waste management, as well as local craftspeople, to understand available materials, such as wood and explore how recycled plastic could work as a strong local alternative.

Based on these insights, in 2024, we equipped the project with a set of machines tailored to local needs: a Mad-Shredder Basic, a Mad-Shredder Pro, an Mad-Extruder for beam and furniture production, and a Mad-Arbor Press Injection machine for making school supplies, coasters, flower pots and more.

-

With these machines, they are now able to transform previously wasted plastics into mainly outdoor furniture and school supplies.

This not only reduces plastic being burnt but also creates new economic opportunities and local jobs.

KENYA

2024

Setting up Kenya’s first humanitarian plastic Fab Lab, in collaboration with the Kenya Red Cross, in Lamu Island.

-

The Kenya Red Cross runs a rehabilitation center on Lamu Island, where there are no local waste management facilities. All waste must be transported over long distances for disposal. Instead of seeing this as only a challenge, they identified an opportunity: to use plastic waste as a resource for teaching youth about recycling, innovation, and creativity, while also providing the rehab center with a practical tool for education and empowerment.

-

The existing fab lab on the island needed more equipment to expand its capacity. The Kenya Red Cross wanted to introduce additional machines to make better use of plastic waste as a raw material for innovation and skill-building among the youth.

-

We supplied and set up a complete set of recycling machines, including the Shredder PRO, Manual Shredder, Arbor Press Injection Machine, Extruder, Sheet Press Mini, and a collection of molds. These tools enabled the lab to transform plastic waste into valuable new products while fostering hands-on learning and creativity.

-

The fablab is now fully equipped to educate the youth from the rehab centre and the island, work on R&D projects, educational workshops, give innovation courses and more.

Portugal

2025

CircuLar: House of the Circular Economy is the result of a partnership between YouthCoop - Cooperative for Development and Citizenship and the Sintra City Council.

-

Create a space for innovation an education on circular economy principles, opened to the local community.

-

LAR Circular is a circular economy center located near Lisbon, dedicated to hands-on education around material reuse and sustainable production. The center works with young people, teaching them practical ways to recycle and reprocess materials such as plastic, paper, and wood, while building awareness of circular design principles.

The centre already had some basic equipment to experiment with plastic, but it wasn’t designed for proper recycling or production, so it was hard to create finished, valuable products.

-

As part of their plastics recycling program, LAR Circular uses several of our machines to guide students through the full recycling process, from waste to finished product. Their setup includes our Mad-Shredder Basic, a compact motorized shredder, alongside a manual shredder, allowing participants to understand both mechanized and human-powered material processing. Recycled plastic is then transformed using an Mad-Arbor press injection machine and a selection of molds, producing everyday objects such as combs, carabiners, and tiles/coasters.

-

By combining education, experimentation, and small-scale production, LAR Circular empowers the next generation with practical skills and a deeper understanding of how materials can stay in use rather than becoming waste.

Sudan

2026

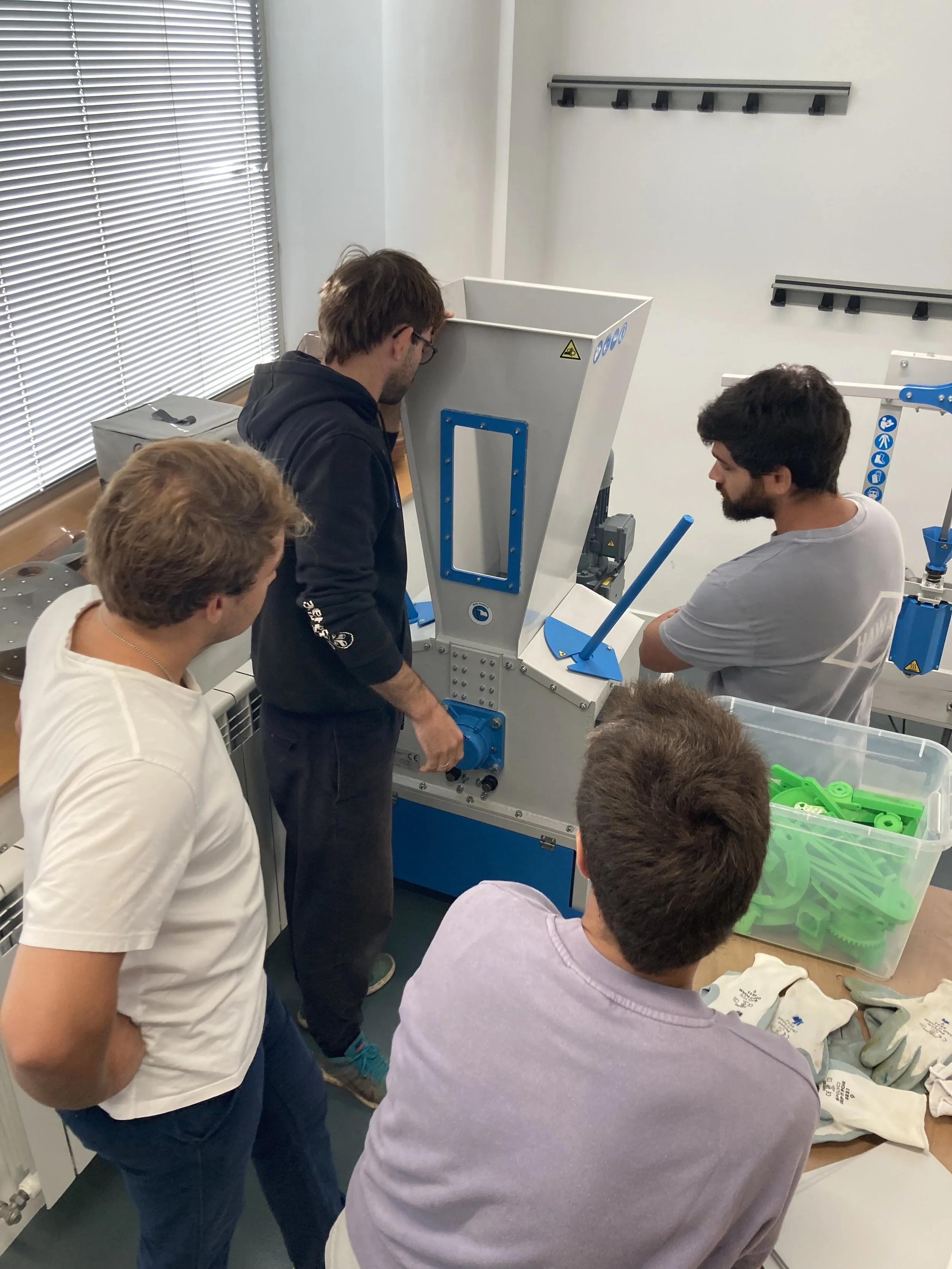

Plastic recycling facility in a peacekeeping base in Sudan in collaboration with UNISFA

-

The main challenge of this project is its implementation within a UN peacekeeping base located in a remote region with no formal waste management infrastructure and a precarious political situation. In addition, difficult logistics, seasonal road accessibility, and long supply chains significantly complicate the transport, installation, and maintenance of industrial equipment.

-

Working with UN partners, we identified that despite the complex operating environment, there was a consistent availability of plastic waste streams suitable for our processes. Unlike typical recycling projects, there is no economic necessity to make the activity financially profitable, as the primary objective is to reduce the volume of waste that must be transported out of the base, which represents a significant logistical and financial cost.

As a result, the focus is on transforming plastic waste into practical objects for on-site use—such as furniture and functional equipment, without introducing unnecessary complexity linked to market sales or profitability.

-

We delivered a full turnkey project, supplying a complete set of plastic recycling machines allowing the production of a wide variety of products, along with all the necessary supporting equipment to operate the workshop independently, including storage solutions, tools, and spare parts. The project includes on-site installation, commissioning, and hands-on training of local operators, ensuring that the system can be run autonomously and sustainably once deployed.

-

The equipment has recently arrived at the base, marking an important milestone for the project. On-site installation and operator training are planned in the coming months, with more updates coming soon.