our machines

Mini collection

Perfect for getting started with plastic recycling, make demos and use it as an educational tool.

bASIC LINE

Ideal for experimenting, make small to medium productions and give educational workshops.

PRO LINE

Efficient and user friendly. Whether you're empowering local communities or launching a new business.

overview

mini collection

Getting started with plastic recycling?

We’ve got your back.

Whether you're building your first setup or experimenting with recycled materials, our affordable and reliable machines are made for tinkerers like you. We’re here to guide you through every step, from choosing the right machine to making your first production.

Our Mini Collection gives you everything you need to start turning plastic waste into new creations.

the mini Collection includes:

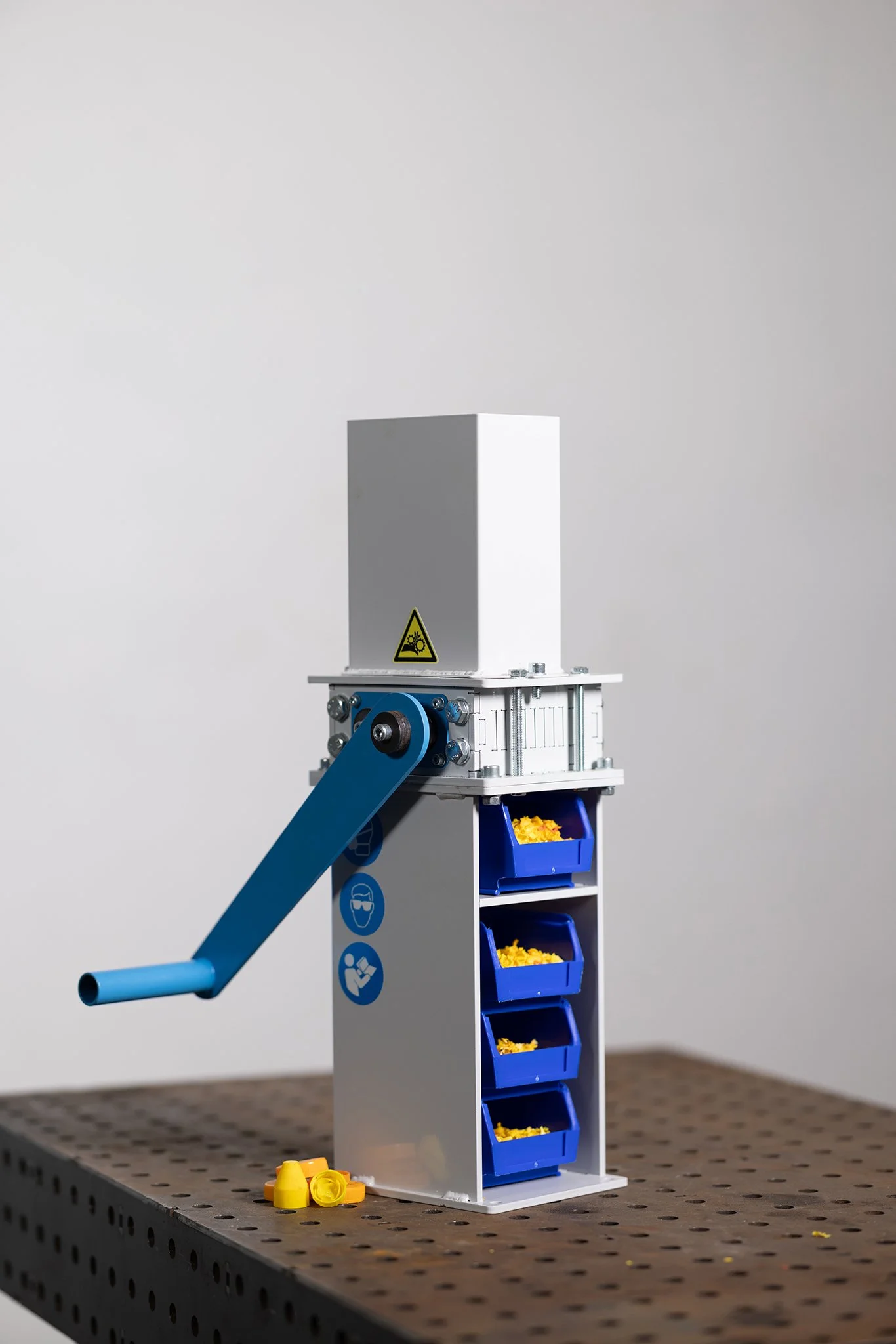

Mini Shredder (Manually operated)

Mini Injector (Manually operated) - COMING SOON

Mini Extruder (Manually operated) - COMING SOON

Mini Filament Maker - COMING SOON

basic line

Educational systems for hands-on learning and prototyping.

For classrooms, workshops, labs and makerspaces, we provide easy-to-use, low-maintenance machines ideal for hands-on education and prototyping while staying safe and approachable. Our Basic Line is perfect for teaching, experimenting, and demonstrating circular design.

the Basic line includes:

Basic Shredder (10 kg/hr)

Basic Arbor Press Injection Machine

Basic Extruder - COMING SOON

Basic Sheet Press (60x60cm sheets).

pro line

Semi- industrial systems for high-impact recycling operations.

We support organizations and entrepreneurs who are building long-term solutions through plastic recycling. From early-stage planning to large-scale deployment, we offer tailored, turnkey systems backed by technical expertise and ongoing support.

Our Pro Line is scalable, efficient, and designed for serious output — whether you're empowering local communities or launching a business.

the Pro Line includes:

Pro Shredder (100 kg/hr)

Pro Granulator - COMING SOON

Pro Extruder (20 kg/hr)

Pro Modular Sheet Press (120x60cm sheets) - NEW!

Do you also need moulds for your new machines? We offer a selection of the best injection moulds. On top of that we make custom moulds on demand, also for the extruders and sheet presses.

Check it out yourself by going through our catalogue below!

faq

-

First, our shredders break plastic waste into small flakes. Then, these flakes can be melted down in one of our melting machines that use pressure and heat to mould the plastic into something new.

We offer different melting processes, which let you create a variety of objects — from sheets and beams to precise and high quality plastic products.

-

Our machines are designed to be easy to use — anyone can get started! While it helps to be a bit handy, we provide clear documentation and offer in-person training when needed to make sure you feel confident running and maintaining the machines.

-

Our machines work with thermoplastics like PP, PE, and PS most effectively, and other resins can be tested too. However, we don’t recommend melting PET because the results aren’t great, and PVC should also be avoided due to the highly toxic fumes it releases.

-

We offer three lines of machines: the MINI line costs a few hundred euros, the BASIC line ranges from €1,000 to €5,000, and the PRO line ranges from €10,000 to €30,000. You can find detailed pricing in our catalogue.

-

Absolutely — this is actually our specialty, and we love doing it. We can provide just the machines, or handle everything from project planning, market research, packing, shipping, and export, to installation, testing, user training, and even connecting you with sales or maintenance partners.

Whether you want a full turnkey solution or just some expert support here and there, we’ve got you covered. -

Our machines are pretty straightforward to maintain. Aside from some occasional greasing and oil changes, regular upkeep is minimal. Most parts are designed to be easily replaced using common components or even remade with accessible tools. For the few specialized parts that aren’t as simple, we’re happy to supply spares no matter where you are.

-

Yes, our machines are CE marked, meaning they meet the essential safety and environmental standards required in Europe. This certification ensures our equipment is reliable and safe to use. We’re committed to maintaining high quality and compliance across all our products.